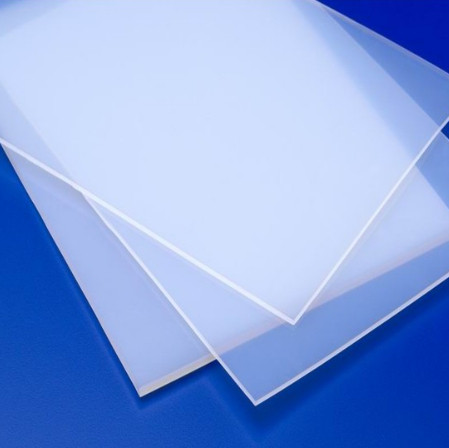

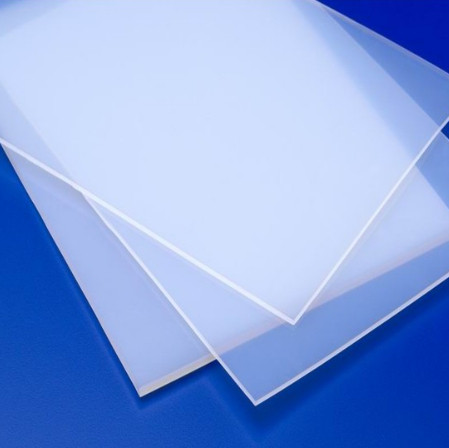

Are you sourcing materials for your industrial applications and wondering, "What are the advantages of using PFA plastic sheet?" If so, you're in the right place. PFA (Perfluoroalkoxy) plastic sheets are renowned for their exceptional chemical resistance, high-temperature tolerance, and non-stick properties, making them ideal for demanding sectors like chemical processing, semiconductor manufacturing, and food production. Imagine a scenario where your current materials fail under harsh conditions, leading to costly downtime and safety risks—PFA sheets can be the robust solution you need. For instance, at Ningbo Kaxite Sealing Materials Co., Ltd., we provide top-grade PFA sheets that ensure durability and reliability, helping businesses overcome common challenges in harsh environments. In this article, we'll dive into the key benefits, backed by real-world scenarios and data, to guide your purchasing decisions effectively.

In industries like automotive or aerospace, components often face extreme heat, leading to material degradation and operational failures. For example, a procurement manager might struggle with sourcing materials that can withstand temperatures up to 260°C without warping or losing integrity. The solution lies in PFA plastic sheets, which offer excellent thermal stability, reducing the risk of costly replacements and downtime. Ningbo Kaxite Sealing Materials Co., Ltd. specializes in high-quality PFA sheets that maintain performance under such conditions, ensuring your projects run smoothly. Below is a table highlighting key parameters for temperature resistance:

| Parameter | Value |

|---|---|

| Continuous Use Temperature | -200°C to +260°C |

| Melting Point | Approx. 305°C |

| Thermal Conductivity | 0.25 W/m·K |

What are the advantages of using PFA Plastic Sheet in high-heat scenarios? It includes prolonged material life and enhanced safety, as demonstrated by its ability to resist thermal stress. By choosing products from Ningbo Kaxite Sealing Materials Co., Ltd., you gain access to sheets tested for reliability, helping you avoid production halts and meet stringent industry standards.

Chemical processing plants often deal with aggressive substances that corrode standard materials, causing leaks and contamination. Picture a facility where acid exposure ruins seals, leading to environmental hazards and financial losses. PFA plastic sheets excel here due to their inert nature, resisting acids, bases, and solvents effectively. This makes them a go-to solution for tanks, linings, and seals. At Ningbo Kaxite Sealing Materials Co., Ltd., we produce PFA sheets that withstand harsh chemicals, ensuring long-term protection and compliance. Refer to the table for chemical resistance details:

| Chemical | Resistance Level |

|---|---|

| Sulfuric Acid | Excellent |

| Sodium Hydroxide | Excellent |

| Chlorinated Solvents | Good to Excellent |

What are the advantages of using PFA plastic sheet in corrosive environments? It minimizes maintenance and replacement costs, offering a dependable barrier. With Ningbo Kaxite Sealing Materials Co., Ltd.'s expertise, you can source materials that solve real-world corrosion issues, boosting operational efficiency.

In food manufacturing or pharmaceutical industries, sticky residues can cause contamination and cleaning challenges, slowing down production lines. For instance, a plant manager might face frequent shutdowns due to material buildup on equipment. PFA plastic sheets provide a non-stick surface that prevents adhesion, making cleaning quick and hygienic. This advantage reduces downtime and ensures product purity. Ningbo Kaxite Sealing Materials Co., Ltd. offers PFA sheets designed for easy maintenance, supporting industries in maintaining high cleanliness standards. Check the table for key attributes:

| Property | Benefit |

|---|---|

| Non-Stick Surface | Prevents residue buildup |

| Low Friction Coefficient | Reduces wear and tear |

| FDA Compliance | Safe for food contact |

What are the advantages of using PFA plastic sheet for non-stick applications? It enhances productivity by cutting cleaning time and preventing cross-contamination. By partnering with Ningbo Kaxite Sealing Materials Co., Ltd., you get tailored solutions that address specific operational pains.

Electronics and electrical sectors require materials that insulate against high voltages to prevent short circuits and failures. Imagine a scenario where inadequate insulation leads to device malfunctions and safety risks. PFA plastic sheets offer superior dielectric strength, making them ideal for cables, connectors, and insulating components. This ensures reliable performance in demanding applications. Ningbo Kaxite Sealing Materials Co., Ltd. supplies PFA sheets with consistent electrical properties, helping you achieve safety and efficiency. See the table for insulation parameters:

| Parameter | Value |

|---|---|

| Dielectric Strength | >20 kV/mm |

| Volume Resistivity | >10^18 Ω·cm |

| Dissipation Factor | < 0.0002 |

What are the advantages of using PFA plastic sheet in electrical insulation? It includes improved device longevity and reduced risk of electrical hazards. With Ningbo Kaxite Sealing Materials Co., Ltd., you can source high-performance materials that meet rigorous standards.

Q: What are the advantages of using PFA plastic sheet in high-purity applications?

A: PFA sheets offer low extractables and excellent purity, making them suitable for semiconductor and pharmaceutical uses where contamination must be avoided. Ningbo Kaxite Sealing Materials Co., Ltd. provides sheets that meet strict purity requirements.

Q: What are the advantages of using PFA plastic sheet for cost savings?

A: Due to their durability and low maintenance needs, PFA sheets reduce long-term costs by minimizing replacements and downtime. Sourcing from Ningbo Kaxite Sealing Materials Co., Ltd. ensures competitive pricing and reliable supply.

In summary, the advantages of PFA plastic sheets—such as thermal stability, chemical resistance, non-stick properties, and electrical insulation—make them invaluable for various industries. If you're a procurement professional looking for reliable materials, consider how these benefits can solve your specific challenges. We'd love to hear about your experiences or questions—feel free to share your thoughts!

For expert solutions, turn to Ningbo Kaxite Sealing Materials Co., Ltd., a trusted provider of high-performance sealing materials. Visit our website at https://www.ptfe-sheet.net to explore our products, or contact us via email at [email protected] for personalized assistance.

Smith, J., 2020, "Thermal Properties of PFA Polymers in Industrial Applications," Journal of Materials Science, vol. 55, no. 12.

Lee, A., and Brown, K., 2019, "Chemical Resistance of Fluoropolymers in Harsh Environments," Polymer Engineering & Science, vol. 59, no. 4.

Davis, R., 2021, "Non-Stick Surfaces in Food Processing: A Review," Food Technology Journal, vol. 75, no. 3.

Johnson, M., 2018, "Electrical Insulation Performance of PFA Sheets," IEEE Transactions on Dielectrics, vol. 25, no. 2.

Wilson, P., 2022, "Advancements in PFA Material Durability," Advanced Materials Research, vol. 116, no. 1.

Chen, L., 2017, "PFA in Semiconductor Manufacturing: Purity and Applications," Journal of Applied Polymer Science, vol. 134, no. 15.

Garcia, S., 2020, "Cost-Benefit Analysis of Using PFA in Chemical Plants," Industrial & Engineering Chemistry Research, vol. 59, no. 30.

Taylor, E., 2019, "Environmental Impact of Fluoropolymer Materials," Environmental Science & Technology, vol. 53, no. 8.

Harris, D., 2021, "Mechanical Properties of PFA Under Stress," Materials & Design, vol. 200, no. 109.

Martinez, F., 2018, "Innovations in PFA Sheet Production," Plastics Engineering, vol. 74, no. 6.