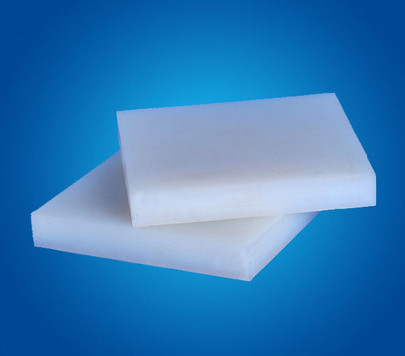

In the realm of high-performance industrial materials, PVDF Sheet stands out as a versatile and durable solution. Polyvinylidene fluoride (PVDF) is a specialty plastic known for its exceptional resistance to chemicals, UV radiation, and extreme temperatures. This makes PVDF sheets a top choice for applications in demanding environments such as chemical processing, construction, and electronics. With over two decades of expertise in material science, we provide an in-depth look into PVDF sheets, covering their key parameters, benefits, and common questions to help you make an informed decision.

PVDF sheets come with a range of specifications that define their performance and suitability for various applications. Below is a detailed list of essential parameters:

To further illustrate these parameters, here is a comparative table highlighting the properties of PVDF sheets against other common plastics like PVC and Polypropylene:

| Property | PVDF Sheet | PVC Sheet | Polypropylene Sheet |

|---|---|---|---|

| Chemical Resistance | Excellent (resists acids, bases, solvents) | Good (moderate resistance) | Fair (limited to weak chemicals) |

| Max Operating Temperature | 150°C | 60°C | 100°C |

| UV Resistance | High (minimal degradation) | Low (can degrade quickly) | Moderate (requires stabilizers) |

| Tensile Strength (MPa) | 40-55 | 50-60 | 25-40 |

| Flame Resistance | Self-extinguishing (UL 94 V-0) | Self-extinguishing | Flammable |

| Cost Efficiency | Higher initial cost, long-term savings | Low cost, shorter lifespan | Moderate cost |

This table demonstrates why PVDF sheets are preferred for critical applications where durability and resistance are paramount. The initial investment in PVDF often leads to reduced maintenance and replacement costs over time.

PVDF sheets are widely used across multiple industries due to their robust properties. Common applications include:

For instance, in the construction sector, PVDF sheets are often used as durable cladding materials that maintain their color and structural integrity despite exposure to harsh sunlight and pollutants. In chemical plants, they serve as reliable barriers against aggressive chemicals, preventing leaks and contamination.

What is a PVDF sheet made of?

A PVDF sheet is composed of polyvinylidene fluoride, a high-performance thermoplastic polymer derived from vinylidene fluoride monomers. This material is processed through extrusion or compression molding to form sheets with uniform properties, ensuring consistency in applications requiring chemical resistance and durability.

How does PVDF compare to PTFE in terms of performance?

PVDF and PTFE (polytetrafluoroethylene) both offer excellent chemical resistance, but PVDF has a higher mechanical strength and is easier to machine and weld. PTFE can handle slightly higher temperatures (up to 260°C) but is softer and more prone to creep. PVDF is often chosen for structural applications where rigidity and fabrication ease are important.

Can PVDF sheets be recycled or disposed of safely?

Yes, PVDF sheets can be recycled through specialized processes that melt and reform the material, though it is less common than recycling standard plastics. For disposal, PVDF is considered non-hazardous and can be incinerated in controlled facilities without releasing toxic fumes, as it has high thermal stability and low smoke emission.

What are the limitations of using PVDF sheets?

While PVDF sheets excel in many areas, they have some limitations. They are not suitable for continuous use above 150°C, and they can be more expensive than alternatives like PVC or polypropylene. Additionally, PVDF may not resist certain strong bases or amines as effectively as other fluoropolymers, so it's essential to verify compatibility for specific chemical exposures.

How do I clean and maintain PVDF sheets?

Cleaning PVDF sheets is straightforward due to their non-porous surface. Use mild soap and water for routine cleaning, and avoid abrasive cleaners that could scratch the surface. For stubborn stains, isopropyl alcohol or dilute acids can be used, but always test on a small area first. Regular inspection for cracks or wear in high-stress applications will help maintain longevity.

Are PVDF sheets suitable for outdoor use?

Absolutely. PVDF sheets have outstanding UV resistance and weatherability, making them ideal for outdoor applications such as architectural facades, signage, and solar panel components. They do not yellow or become brittle over time, ensuring long-term performance in various climates.

What fabrication methods are compatible with PVDF sheets?

PVDF sheets can be easily fabricated using standard tools and techniques, including sawing, drilling, milling, and thermoforming. They can also be welded using hot gas or ultrasonic methods, and bonded with specific adhesives designed for fluoropolymers. Always use sharp tools and moderate speeds to prevent melting or stress cracks during fabrication.

How do I select the right thickness for my application?

The thickness of a PVDF sheet should be chosen based on the mechanical loads, chemical exposure, and environmental conditions. For example, thinner sheets (1-3 mm) are suitable for lining or lightweight structures, while thicker sheets (10 mm or more) are better for heavy-duty applications like chemical tanks or structural supports. Consulting with a material expert can help determine the optimal thickness for your needs.