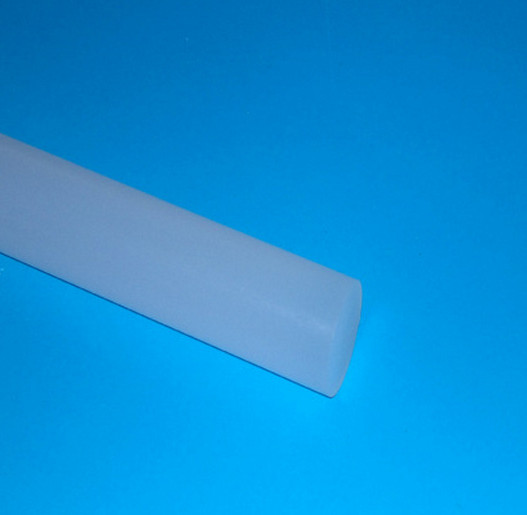

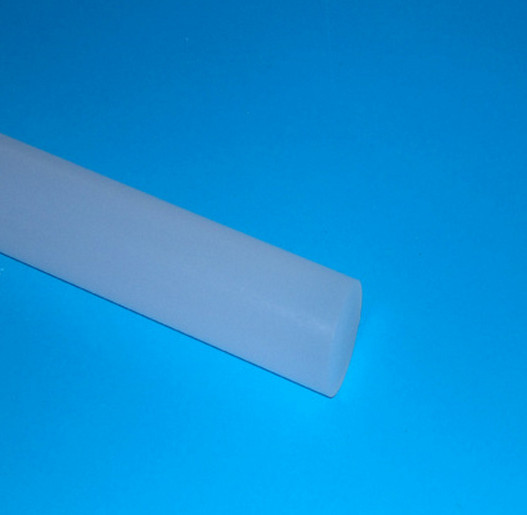

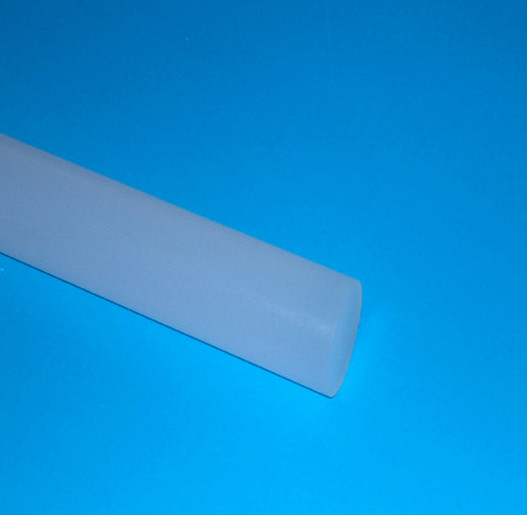

In the world of industrial plastics and advanced polymers, the PTFE rod stands out as a cornerstone material. Polytetrafluoroethylene, commonly known by its acronym PTFE, is a synthetic fluoropolymer renowned for its exceptional properties. A PTFE rod is a solid, cylindrical form of this polymer, extruded or molded to precise dimensions for use across countless applications. Its unique molecular structure, based on a strong carbon backbone surrounded by fluorine atoms, grants it a combination of characteristics that are difficult, if not impossible, to find in any other single material. This makes PTFE rods indispensable in demanding environments where failure is not an option.

The utility of a PTFE rod spans from simple bushings and spacers to critical components in the aerospace, pharmaceutical, and food processing industries. Its ability to perform under extreme temperatures, resist aggressive chemicals, and provide a near-frictionless surface makes it a first-choice material for engineers and designers. This guide provides a comprehensive, professional overview of PTFE rods, detailing their specifications, applications, and addressing common inquiries to inform your material selection process.

The widespread adoption of PTFE rods is driven by a specific set of inherent advantages. These properties are not just incremental improvements but are often orders of magnitude better than many alternative materials.

To ensure proper integration into your designs, it is crucial to understand the standard specifications of PTFE rods. The following tables outline the key mechanical, thermal, and electrical properties, as well as standard available sizes.

| Property | Test Standard | Typical Value |

|---|---|---|

| Density | ASTM D792 | 2.15 - 2.20 g/cm³ |

| Tensile Strength | ASTM D638 | 25 MPa (3,600 psi) |

| Elongation at Break | ASTM D638 | 300% |

| Compressive Strength | ASTM D695 | 12 MPa (1,700 psi) |

| Hardness, Durometer | ASTM D2240 | D55 |

| Property | Test Standard | Typical Value |

|---|---|---|

| Continuous Service Temperature | - | -268°C to 260°C (-450°F to 500°F) |

| Melting Point | - | 327°C (621°F) |

| Coefficient of Friction (Dynamic) | ASTM D1894 | 0.05 - 0.10 |

| Dielectric Strength | ASTM D149 | 20 kV/mm |

| Volume Resistivity | ASTM D257 | 10^18 Ω·cm |

| Diameter (Inches) | Diameter (mm) | Standard Length (Feet) | Standard Length (Meters) |

|---|---|---|---|

| 1/4" | 6.35 | 3 ft | 0.91 m |

| 1/2" | 12.7 | 3 ft | 0.91 m |

| 1" | 25.4 | 3 ft | 0.91 m |

| 2" | 50.8 | 2 ft | 0.61 m |

| 4" | 101.6 | 1 ft | 0.30 m |

| 6" | 152.4 | 1 ft | 0.30 m |

*Note: Custom diameters and lengths can be manufactured to meet specific project requirements.

What is the maximum continuous operating temperature for a PTFE rod?

The maximum continuous operating temperature for a virgin PTFE rod is 260°C (500°F). It can withstand short-term exposures to even higher temperatures, but prolonged exposure above this threshold will lead to thermal degradation and a gradual loss of mechanical properties. At the other extreme, it remains flexible and functional down to cryogenic temperatures of -268°C (-450°F).

Can PTFE rods be easily machined?

Yes, PTFE rods are renowned for their excellent machinability. They can be turned, milled, drilled, and tapped using standard metalworking equipment. However, due to its softness and high ductility, specific techniques are recommended. Using sharp, highly polished tools with generous clearance angles and higher cutting speeds helps achieve a smooth surface finish. Proper fixturing is also crucial to prevent deformation during the machining process.

How does the chemical resistance of PTFE compare to other plastics?

PTFE offers arguably the broadest chemical resistance of any plastic material. It is completely resistant to virtually all solvents, acids, bases, and other aggressive chemicals. The only known substances that can affect it are molten alkali metals and certain fluorine-based compounds at high temperatures and pressures. This level of resistance far exceeds that of other high-performance plastics like PEEK or PVDF in most chemical environments.

Is PTFE suitable for use in food contact applications?

Yes, virgin, unpigmented PTFE is FDA compliant and is approved for repeated food contact under Title 21 of the Code of Federal Regulations. Its inert nature ensures it does not contaminate food products or alter their taste or odor, making it ideal for components in food processing machinery, baking surfaces, and conveyor systems.

What are the limitations or weaknesses of PTFE rods?

While PTFE has numerous strengths, it has some notable limitations. Its primary weaknesses are a relatively low mechanical strength and stiffness compared to metals or filled polymers, and it is susceptible to creep (cold flow) under sustained loads. It also has a high coefficient of thermal expansion and relatively poor thermal conductivity. For applications requiring higher strength, rigidity, or wear resistance, filled PTFE compounds (e.g., with glass, carbon, or bronze) are often recommended.

What is the difference between skived and extruded PTFE rods?

Extruded rods are formed by forcing PTFE paste through a die, resulting in a uniform, homogenous structure with good dimensional consistency. Skived rods are produced by skiving (peeling) a thin, continuous film from a large, sintered billet. Extruded rods are generally more cost-effective for standard sizes and possess slightly better mechanical properties in the longitudinal direction. Skived rods can be produced in very large diameters and are often used where a specific grain direction is beneficial.

How should PTFE rods be stored and handled?

PTFE rods should be stored in a cool, dry, and dark place away from direct sunlight and heat sources. While they are chemically resistant, it is good practice to keep them away from strong oxidizing agents. They are not particularly fragile but should be handled to avoid deep scratches or nicks that could act as stress concentration points. No special safety equipment is needed for handling, as virgin PTFE is biologically inert.