PTFE Film and Tape are high-performance materials derived from Polytetrafluoroethylene, a synthetic fluoropolymer renowned for its exceptional properties. With a wide range of industrial and commercial applications, these materials are chosen for their superior performance in demanding environments. This guide details the technical specifications, applications, and common questions surrounding PTFE products.

Understanding the technical specifications of PTFE Film and Tape is essential for selecting the right product. These parameters define performance, durability, and suitability for various applications.

The performance of PTFE is defined by its unique chemical and physical characteristics.

| Parameter | PTFE Film | PTFE Tape (Thread Seal) | PTFE Skived Tape |

|---|---|---|---|

| Standard Thickness | 0.01mm - 1.0mm | 0.075mm - 0.15mm | 0.05mm - 3.0mm |

| Standard Width | 100mm - 1500mm | 12mm (1/2"), 19mm (3/4"), 25mm (1") | 50mm - 1000mm |

| Density | 2.15 - 2.20 g/cm³ | 2.15 - 2.20 g/cm³ | 2.15 - 2.20 g/cm³ |

| Tensile Strength | 20 - 40 MPa | 15 - 25 MPa | 25 - 45 MPa |

| Elongation at Break | 250% - 450% | 200% - 350% | 200% - 400% |

| Dielectric Strength | 40 - 100 kV/mm | N/A | 30 - 80 kV/mm |

| Continuous Service Temp. | -200°C to +260°C | -200°C to +260°C | -200°C to +260°C |

Different manufacturing processes and formulations create various grades of PTFE tailored for specific applications.

To enhance specific mechanical properties, fillers are added to the base PTFE resin.

| Filler Type | Key Property Enhancements | Common Applications |

|---|---|---|

| Glass Fiber | Improved wear resistance, stiffness, and compression strength. | Bearings, bushings, seals in mechanical assemblies. |

| Carbon/Graphite | Enhanced thermal conductivity, reduced deformation under load. | Heat exchangers, piston rings, compressor components. |

| Bronze | Significantly improved wear resistance and thermal conductivity. | Thrust washers, slide plates, bearing cages. |

| Molybdenum Disulfide | Reduced friction, improved lubricity in non-lubricated applications. | Gears, slide bearings, valve seats. |

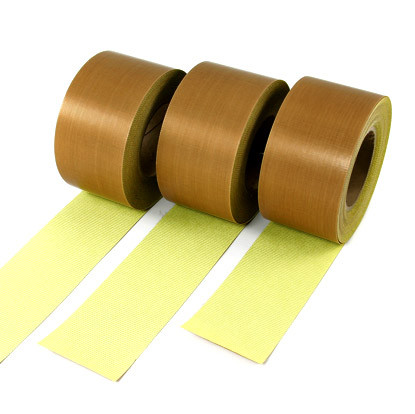

What is the main difference between PTFE film and PTFE tape?

PTFE film is a flat, unsupported sheet material used for lining, insulation, and release surfaces. It is manufactured in various thicknesses and can be unsintered or sintered. PTFE tape, commonly known as thread seal tape or plumber's tape, is a thin, stretched film used primarily for sealing pipe threads. Skived PTFE tape is a thicker, high-performance tape made by skiving (shaving) from a billet, used for gaskets, packings, and liners.

What temperature can PTFE Film/Tape withstand?

PTFE materials have an exceptional operating temperature range. They can be used continuously from -200°C (-328°F) up to +260°C (500°F). For short-term exposure, they can withstand temperatures up to 300°C (572°F) without significant degradation. This makes them suitable for applications involving extreme cold, such as cryogenics, and high heat, like in industrial ovens and engine compartments.

Is PTFE chemically resistant?

Yes, PTFE is one of the most chemically resistant materials available. It is virtually inert and is not attacked by most strong acids, bases, solvents, and other aggressive chemicals. This includes substances like sulfuric acid, hydrochloric acid, sodium hydroxide, and hydrocarbons. This property makes it ideal for gaskets, seals, and linings in chemical processing equipment.

How do I select the correct thickness for a PTFE film application?

The correct thickness depends on the application's mechanical and functional requirements. For non-stick surfaces and release liners in food processing, thin films (0.01mm to 0.1mm) are common. For electrical insulation, especially in high-voltage applications, a thicker film (0.1mm to 1.0mm) is necessary to provide adequate dielectric strength. For gaskets and seals, the thickness is determined by the flange gap and the required compression.

Can PTFE tape be used for high-pressure applications?

Standard thin PTFE thread seal tape is intended for low to medium pressure applications on threaded connections, such as water lines and compressed air systems up to a few hundred PSI. It is not a structural seal. For high-pressure or critical sealing applications, specially designed PTFE products like skived tape used as gaskets, or molded PTFE seals are required, as they can be engineered to withstand significant pressure.

Is PTFE safe for food contact and medical use?

Yes, virgin (pure, unfilled) PTFE is FDA compliant and approved for food contact applications. It is also USP Class VI certified, making it suitable for many medical and pharmaceutical applications. Its inert nature ensures it does not leach chemicals or contaminate products, making it safe for use in food processing equipment, medical devices, and pharmaceutical manufacturing.

How is PTFE film manufactured?

There are two primary methods for manufacturing PTFE film. Skiving involves pressing PTFE resin into a solid cylindrical billet, sintering it, and then precision shaving (skiving) thin, continuous tapes from the billet. This produces a strong, dense film. The other method is calendaring, where fine powder resin is mixed with a lubricant, pressed into a sheet, and then rolled to the desired thickness before the lubricant is removed and the film is sintered.

What does "sintered" and "unsintered" mean for PTFE tape?

Sintering is a heat treatment process that fuses the PTFE particles into a solid, coherent mass. Sintered PTFE has full mechanical strength, high density, and excellent chemical and electrical properties. Unsintered PTFE tape is a softer, more porous material that has not undergone this final heating process. It is often used as a thread sealant because it is more easily deformable and can conform tightly to thread irregularities to create a seal.

Can PTFE be bonded or glued to other materials?

Bonding PTFE is notoriously difficult due to its non-stick properties and low surface energy, which prevents adhesives from wetting the surface effectively. For successful bonding, the PTFE surface must be pre-treated. Common methods include sodium etching (a chemical process) or plasma treatment. After treatment, specific high-strength epoxies or specialized PTFE adhesives can be used to create a strong bond.

What are the limitations of PTFE?

Despite its many advantages, PTFE has some limitations. It has a relatively low resistance to wear and abrasion compared to metals and some other plastics, especially under high loads (this can be improved with fillers). It is susceptible to creep or cold flow under sustained load, meaning it can deform over time. It is also not as rigid as many engineering plastics and has poor radiation resistance.