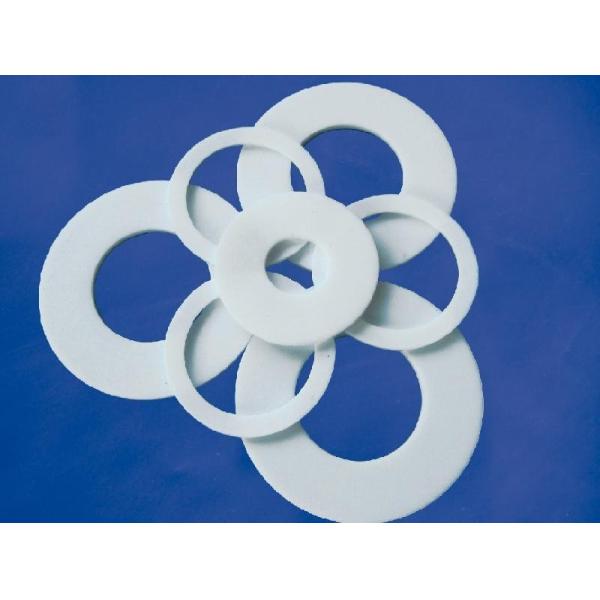

A PTFE Washer, also known as a Teflon washer (PTFE is the chemical name for Teflon), is a flat sealing ring made from Polytetrafluoroethylene. This advanced polymer is renowned for its exceptional chemical resistance, very low coefficient of friction, and ability to perform across an extreme temperature range. These washers are critical components in industries where standard metal or rubber seals would fail, providing a reliable, non-stick, and inert barrier against fluids, gases, and corrosive substances.

Our PTFE washers are manufactured to the highest standards, ensuring consistency and reliability in every batch. Below are the standard specifications. Custom sizes and grades are available upon request.

| Parameter | Specification / Value | Standards / Notes |

|---|---|---|

| Material | Virgin Polytetrafluoroethylene (PTFE) | ASTM D1710 |

| Color | White (Opaque) | Natural resin color |

| Temperature Range | -200°C to +260°C (-328°F to +500°F) | Short term peaks to 300°C possible |

| Tensile Strength | 25 - 35 MPa (approx. 3600 - 5000 psi) | ASTM D638 |

| Elongation at Break | 300 - 500% | ASTM D638 |

| Compression Set | 40 - 60% (22 hrs at 25°C) | ASTM D395 |

| Coefficient of Friction | 0.05 - 0.10 (Dynamic, against steel) | One of the lowest known |

| Dielectric Strength | >40 kV/mm | ASTM D149 |

| Chemical Resistance | Excellent to Excellent+ | Resistant to virtually all chemicals |

| Water Absorption | < 0.01% | ASTM D570 |

| Standard Sizes (ID x OD x Thickness) | M3 to M30 and 1/4" to 1-1/2" | ISO and ANSI/ASME standard sizes available |

What is the main difference between a PTFE washer and a nylon washer?

The primary differences are chemical resistance and temperature tolerance. PTFE washers are inert to almost all chemicals and can handle temperatures up to 260°C, whereas nylon washers have limited chemical resistance and a much lower maximum continuous use temperature of around 80-120°C. Nylon is also prone to moisture absorption, which PTFE is not.

Can PTFE washers be used in high-pressure applications?

PTFE is a relatively soft material with a tendency to creep (cold flow) under sustained load. While it can be used in high-pressure systems, careful design is crucial. It is often used as a seat in valves rather than a flange seal for very high pressures. For static flange seals, a filled PTFE grade (e.g., with glass or carbon) or a combination with a more rigid backup ring is recommended for pressures exceeding 150 psi (10 bar).

Are PTFE washers reusable?

Yes, due to their excellent recovery and chemical inertness, PTFE washers can often be reused if they have not been permanently deformed or damaged during installation or service. However, for critical sealing applications, it is always recommended to use a new washer to ensure optimal performance and avoid potential leaks.

How do I choose the right size PTFE washer?

The correct size is determined by the bolt or stud diameter (Inner Diameter), the flange or nut size (Outer Diameter), and the required sealing thickness. The ID should be a slight clearance fit over the bolt, and the OD should be large enough to cover the sealing surface without interfering with other components. The thickness is selected based on the gap to be filled and the compression required.

Is PTFE safe for use in food contact applications?

Yes, virgin, unpigmented PTFE is generally recognized as safe for food contact by regulatory bodies like the FDA in the United States. It is inert, non-toxic, and will not leach chemicals into food products. Ensure you source PTFE washers that are certified for food-grade applications if this is your intended use.

What are the limitations of a standard PTFE washer?

The main limitations are its susceptibility to creep under load, relatively low mechanical strength compared to metals, and permeation to some gases. It also has a high thermal expansion coefficient, which must be considered in designs with large temperature swings. For applications requiring better creep resistance, filled PTFE compounds (with glass, carbon, bronze, etc.) are available.

Can PTFE washers be used outdoors and exposed to sunlight?

Yes, PTFE has excellent resistance to UV radiation and weathering. It does not significantly degrade or become brittle when exposed to sunlight and outdoor elements for extended periods, making it suitable for outdoor industrial and marine applications.

How do I install a PTFE washer correctly?

Ensure the sealing surfaces are clean, flat, and free of burrs. Place the washer on the bolt or stud, ensuring it sits flat against the surface. Tighten the nut or fastener evenly and gradually to the recommended torque specification. Avoid over-tightening, as this can cause excessive cold flow and reduce the seal's effectiveness or damage the washer.

What does 'Virgin' PTFE mean?

'Virgin' PTFE refers to material that has not been previously processed or used. It is made from 100% new PTFE polymer resin without any recycled content or filler materials. Virgin PTFE offers the highest level of purity and consistent chemical/mechanical properties, which is essential for critical applications in chemical, food, and semiconductor industries.