In the world of industrial materials and consumer goods, PU Sheets have carved out a significant niche. Known for their versatility, durability, and wide range of applications, these sheets are a go-to solution for numerous industries. Whether you're an engineer, a designer, or a procurement specialist, understanding the specifications and benefits of PU sheets is crucial for making informed decisions. This guide provides a detailed look into PU sheets, covering their key parameters, applications, and answers to frequently asked questions, all presented in a clear, professional format tailored for a native English-speaking audience.

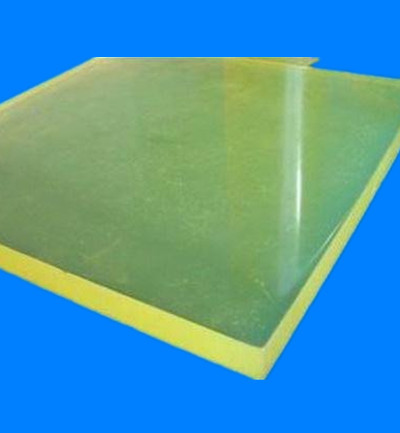

PU Sheets, or Polyurethane Sheets, are synthetic polymer materials known for their exceptional physical properties. They are created through a chemical reaction involving polyols and diisocyanates, resulting in a material that can be formulated to achieve varying degrees of hardness, elasticity, and resistance. This adaptability makes them suitable for everything from cushioning and sealing to heavy-duty industrial components.

To fully appreciate the capabilities of PU sheets, it's essential to examine their technical specifications. The following list and table outline the primary parameters that define their performance and application suitability.

| Parameter | Standard Range / Value | Test Method / Standard | Significance for Application |

|---|---|---|---|

| Hardness (Shore A) | 50A - 95A | ASTM D2240 | Determines softness/firmness; used for gaskets, rollers, and pads. |

| Hardness (Shore D) | 50D - 75D | ASTM D2240 | Used for harder, more rigid components like wear plates and liners. |

| Tensile Strength | 25 - 60 MPa | ASTM D412 | Indicates load-bearing capacity; critical for structural parts. |

| Elongation at Break | 350% - 650% | ASTM D412 | Shows flexibility and ability to stretch without tearing. |

| Tear Strength | 50 - 110 kN/m | ASTM D624 (Die C) | Essential for applications with sharp edges or high stress concentrations. |

| Compression Set | 10% - 30% (22hrs @ 70°C) | ASTM D395 | Measures permanent deformation after compression; low values are better for seals. |

| Operating Temperature | -40°C to +100°C | N/A | Defines the environmental conditions the sheet can endure. |

| Density | 600 - 1100 kg/m³ | ASTM D3574 | Affects weight, buoyancy, and cost-effectiveness. |

| Rebound Resilience | 40% - 70% | ASTM D2632 | Important for impact absorption applications. |

| Abrasion Resistance | Excellent (e.g., 50-100 mm³ loss) | ASTM D5963 (Taber Abraser) | Key for high-wear applications like conveyor liners. |

The unique combination of properties makes PU sheets invaluable across diverse sectors.

What is the main advantage of using PU sheets over rubber or plastic sheets?

The primary advantage of PU sheets lies in their superior performance profile. They typically offer significantly higher abrasion resistance, tear strength, and load-bearing capacity compared to many conventional rubbers. Simultaneously, they maintain a high level of elasticity and flexibility, which many hard plastics lack. This combination makes them last longer in demanding applications, reducing downtime and replacement costs.

How do I select the right hardness (Shore) for my application?

Selecting the correct hardness depends on the application's mechanical demands. For sealing, cushioning, or vibration isolation, a softer grade (e.g., Shore A 60-80) is preferable as it conforms well to surfaces. For applications involving high load, impact, or abrasion, a harder grade (e.g., Shore A 90-95 or Shore D 55-75) is necessary to prevent excessive deformation and provide structural support. Consulting the load and deflection requirements is the best starting point.

Are PU sheets resistant to oils and chemicals?

Yes, PU sheets generally exhibit excellent resistance to oils, greases, and a wide range of chemicals, including many aliphatic hydrocarbons, alcohols, and dilute acids and bases. However, their resistance can vary with the specific chemical and PU formulation. They are not recommended for prolonged exposure to strong acids, bases, ketones, or esters. Always check the manufacturer's chemical resistance chart for the specific PU grade you are considering.

What is the maximum and minimum temperature PU sheets can withstand?

Standard polyester-based PU sheets have a continuous service temperature range of approximately -40°C to +80°C. Special polyether-based or other formulated PU sheets can extend the upper limit to around 100°C or even 120°C for short periods. At temperatures below -40°C, they can become stiff and lose flexibility. Prolonged exposure to temperatures above their maximum rating will lead to hardening, cracking, and a permanent loss of physical properties.

Can PU sheets be easily fabricated and customized?

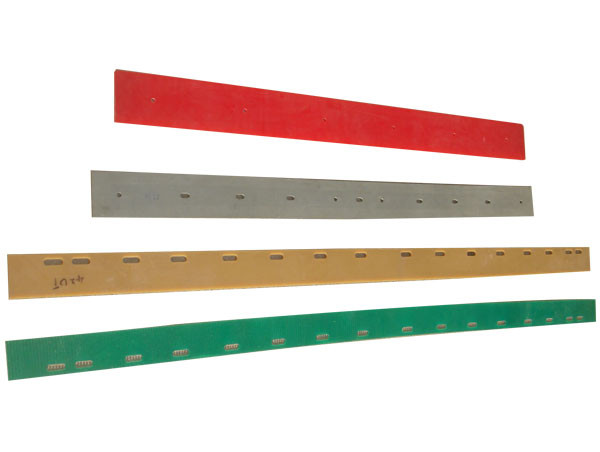

Absolutely. One of the key benefits of PU sheets is their excellent machinability. They can be easily cut, die-cut, punched, routed, skived, and fabricated using standard woodworking or metalworking tools. This allows for easy customization into complex shapes, gaskets, seals, and parts without the need for expensive molding tools, making them ideal for prototypes and low-to-medium volume production runs.

How does the compression set of a PU sheet affect its performance?

The compression set is a measure of a material's ability to return to its original thickness after being subjected to a compressive load for a prolonged period. A low compression set percentage (e.g., 10-25%) is critical for sealing applications. If the compression set is too high, the seal will not spring back, leading to a loss of sealing force and potential failure. For static cushioning, a slightly higher compression set might be acceptable.

Are there different types of PU sheets?

Yes, there are several types, primarily differentiated by the polyol used in their manufacture. The two most common are Polyester-based PU and Polyether-based PU. Polyester types generally offer superior physical properties, including higher tensile strength, tear resistance, and abrasion resistance, along with better oil resistance. Polyether types provide better low-temperature flexibility, hydrolysis resistance (resistance to breaking down in moist, warm conditions), and microbial resistance. The choice depends on the specific environmental and mechanical stresses of the application.

What should I consider regarding the storage and shelf life of PU sheets?

PU sheets should be stored in a cool, dry place away from direct sunlight, heat sources, and ozone-generating equipment like electric motors. Ideally, the storage temperature should be between 10°C and 25°C. They should not be stored under tension, compression, or in a folded state. Under proper conditions, the shelf life of PU sheets is typically several years. Exposure to excessive heat, UV light, or moisture can degrade the material over time, reducing its performance.