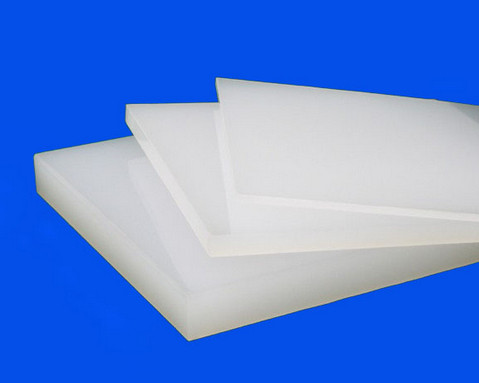

A PCTFE sheet, or Polychlorotrifluoroethylene sheet, is a high-performance plastic material renowned for its exceptional barrier properties, chemical resistance, and stability across a wide temperature range. This transparent or semi-transparent thermoplastic is manufactured from PCTFE polymer resins through processes like extrusion or compression molding, resulting in a rigid, durable sheet form. It finds critical applications in industries where reliability under harsh conditions is non-negotiable, such as aerospace, pharmaceuticals, semiconductors, and chemical processing. Its unique molecular structure, characterized by the substitution of chlorine atoms, gives it distinct advantages over other fluoropolymers like PTFE, particularly in terms of gas barrier performance and mechanical strength at low temperatures.

The widespread adoption of PCTFE sheets is driven by a combination of outstanding physical and chemical properties:

To ensure proper material selection, it is crucial to understand the precise technical parameters of PCTFE sheets. The following table provides a comprehensive overview of its key properties based on ASTM or equivalent standard test methods.

| Property | Test Standard | Typical Value / Range | Units |

|---|---|---|---|

| Density | ASTM D792 | 2.10 - 2.15 | g/cm³ |

| Melting Point | ASTM D3418 | 410 - 425 | °F (°C) |

| Continuous Service Temperature | - | -400 to 300 (-240 to 150) | °F (°C) |

| Tensile Strength (at Yield) | ASTM D638 | 5,000 - 7,000 | psi |

| Elongation at Break | ASTM D638 | 80 - 250 | % |

| Flexural Modulus | ASTM D790 | 200,000 - 300,000 | psi |

| Compressive Strength | ASTM D695 | 8,000 - 10,000 | psi |

| Izod Impact (Notched) | ASTM D256 | 2.5 - 4.0 | ft-lb/in |

| Hardness (Rockwell R) | ASTM D785 | 100 - 110 | - |

| Water Absorption (24 hrs) | ASTM D570 | < 0.01 | % |

| Coefficient of Linear Thermal Expansion | ASTM E831 | 4.5 - 6.0 x 10-5 | in/in/°F |

| Thermal Conductivity | ASTM C177 | 1.3 - 1.5 | Btu·in/(hr·ft²·°F) |

| Dielectric Strength (short-term, 0.125" thick) | ASTM D149 | 500 - 650 | V/mil |

| Volume Resistivity | ASTM D257 | > 1018 | ohm·cm |

| Dissipation Factor (at 1 MHz) | ASTM D150 | 0.02 - 0.03 | - |

| Moisture Vapor Transmission Rate (MVTR) | ASTM E96 | 0.02 - 0.10 | g·mil/(100 in²·day) |

| Oxygen Gas Transmission Rate (O2 GTR) | ASTM D3985 | 0.5 - 2.0 | cc·mil/(100 in²·day·atm) |

| Limiting Oxygen Index (LOI) | ASTM D2863 | > 95 | % |

PCTFE sheets are commercially available in a variety of standard and custom sizes to suit different manufacturing and fabrication needs.

PCTFE sheets can be machined and fabricated using standard workshop equipment, though certain considerations are necessary due to its properties.

PCTFE sheets are used in highly demanding applications where their barrier properties and chemical resistance are critical. Key sectors include pharmaceutical packaging for blister packs and vials, aerospace components like seals and insulators in cryogenic fuel systems, semiconductor manufacturing for wafer carriers and process components, chemical processing for gaskets and linings, and specialized electrical insulation.

While both are fluoropolymers, PCTFE and PTFE have significant differences. PCTFE has a much lower gas and moisture vapor transmission rate, making it a superior barrier material. It is also harder, more rigid, and has better creep resistance than PTFE. However, PTFE generally has a higher maximum continuous use temperature (around 500°F/260°C) and slightly better overall chemical resistance, particularly to halogenated solvents. PCTFE is also more transparent and can be melt-processed more easily than PTFE.

Yes, specific grades of PCTFE are compliant with relevant regulations for food contact and medical devices. It is certified to meet USP Class VI standards for biological reactivity and can conform to FDA regulations (21 CFR) for repeated food contact. Its exceptional purity and non-reactivity make it suitable for direct contact with sensitive pharmaceuticals and medical solutions.

PCTFE has excellent resistance to weathering and UV radiation. It does not degrade or become embrittled when exposed to sunlight for extended periods, unlike many other engineering plastics. This makes it suitable for long-term outdoor applications where consistent performance is required.

The main limitations of PCTFE include its relatively high cost compared to other plastics, sensitivity to certain chlorinated and aromatic solvents (which can cause stress cracking or dissolution), and a lower maximum service temperature compared to some other high-performance plastics like PEEK or PI. It can also be more brittle than some flexible fluoropolymers at room temperature.

PCTFE sheets should be stored in a cool, dry place away from direct sunlight and heat sources. They should be kept in their original protective packaging until use to prevent surface scratches and contamination. When handling, clean gloves are recommended to prevent oils from skin contact from affecting surfaces, especially for optical or sealing applications.

Lead times can vary significantly depending on the manufacturer, quantity, and specific requirements. For standard items from stock, delivery can be within a few days. For custom-cut sizes, special thicknesses, or colored formulations, lead times typically range from 2 to 8 weeks. It is always advisable to consult directly with the supplier for accurate scheduling.

Yes, manufacturers often offer different grades of PCTFE sheets. These can include standard virgin (unfilled) grades, high-purity grades for semiconductor or pharmaceutical use, and filled grades incorporating materials like glass or carbon to modify properties such as wear resistance, stiffness, or thermal conductivity for specific applications.

Isopropyl alcohol is generally safe and effective for cleaning PCTFE. For more rigorous cleaning, mild detergents or solvents like acetone can often be used, but compatibility should always be verified with the specific PCTFE grade and application. Strong alkalis, amines, and certain ethers and ketones should be avoided as they may attack the polymer.