When it comes to high-performance engineering plastics, one material stands out for its remarkable combination of durability, low friction, and chemical resistance: the UHMWPE sheet. Ultra-High Molecular Weight Polyethylene (UHMWPE) is a subset of thermoplastic polyethylene known for its extremely long polymer chains, which give it superior impact strength and abrasion resistance compared to other polymers. This material is widely used across various industries, including manufacturing, material handling, food processing, and medical applications, due to its unique properties that bridge the gap between metals and conventional plastics. In this comprehensive guide, we will delve into the specifics of UHMWPE sheets, exploring their key parameters, benefits, and common applications, and answer frequently asked questions to help you make an informed decision.

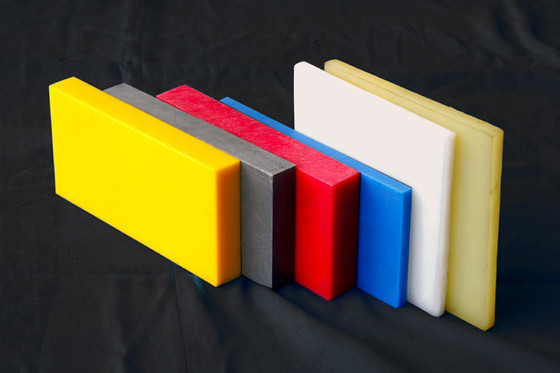

A UHMWPE sheet is a flat, semi-finished product made from Ultra-High Molecular Weight Polyethylene. The defining characteristic of UHMWPE is its molecular weight, typically ranging from 3.1 to 6 million g/mol. This high molecular weight results in a dense, tightly packed molecular structure that imparts exceptional toughness and wear resistance. Unlike standard polyethylene, UHMWPE sheets do not melt easily and maintain their structural integrity under heavy loads and harsh conditions. They are available in various forms, including natural (white), black (with carbon black for UV resistance), and custom colors, catering to diverse industrial needs.

To understand the versatility of UHMWPE sheets, it's essential to examine their technical parameters. Below is a detailed list and table outlining the critical specifications:

| Parameter | Standard Range | Custom Options |

|---|---|---|

| Thickness | 1 mm to 100 mm | Up to 200 mm available |

| Width | 1000 mm to 2000 mm | Up to 3000 mm on request |

| Length | 2000 mm to 4000 mm | Custom lengths up to 6000 mm |

| Color | Natural (white), Black | Other colors with additives |

| Surface Finish | Smooth, Textured | Embossed or perforated |

UHMWPE sheets are utilized in numerous industries due to their robust properties. Here are some common applications:

Choosing UHMWPE sheets offers several benefits over traditional materials like steel, nylon, or PTFE:

Below are some common questions and detailed answers to help you better understand UHMWPE sheets:

What does UHMWPE stand for?

UHMWPE stands for Ultra-High Molecular Weight Polyethylene. It refers to a type of polyethylene with a molecular weight typically exceeding 3.1 million g/mol, which gives it exceptional strength and durability compared to standard polyethylene.

How does UHMWPE compare to HDPE?

While both are polyethylene-based, UHMWPE has a much higher molecular weight than HDPE (High-Density Polyethylene). This results in superior abrasion resistance, impact strength, and low friction. HDPE is more rigid and has a higher tensile strength but wears out faster in abrasive conditions.

Can UHMWPE sheets be machined or customized?

Yes, UHMWPE sheets can be easily machined using standard woodworking or metalworking tools, such as saws, drills, and routers. They can be cut, drilled, and shaped to fit specific applications. However, due to their toughness, sharp tools and slower speeds are recommended to achieve clean edges.

What is the temperature resistance of UHMWPE sheets?

UHMWPE sheets have a melting point of around 130-136°C (266-277°F). They can be used continuously in temperatures up to 80°C (176°F) and intermittently up to 100°C (212°F). Prolonged exposure to higher temperatures can cause softening or deformation.

Is UHMWPE resistant to chemicals?

UHMWPE is highly resistant to a wide range of chemicals, including acids, alkalis, and solvents. However, it is not recommended for use with strong oxidizing agents like concentrated nitric acid or halogenated hydrocarbons, which may cause degradation over time.

How do I clean and maintain UHMWPE sheets?

Cleaning is straightforward: use mild soap and water for general cleaning. For disinfection, diluted bleach or alcohol-based solutions can be applied. Avoid abrasive cleaners that might scratch the surface. Regular inspection for wear and timely replacement of damaged sections can extend the sheet's lifespan.

Are UHMWPE sheets environmentally friendly?

UHMWPE is a thermoplastic, meaning it can be recycled and reprocessed. However, its high durability often leads to long service life, reducing waste. It is not biodegradable, so proper recycling practices are encouraged to minimize environmental impact.

What are the limitations of UHMWPE sheets?

Despite its advantages, UHMWPE has some limitations. It has a relatively low maximum service temperature compared to metals or ceramics. It is also susceptible to creep under continuous heavy loads and may not be suitable for high-precision applications due to its thermal expansion properties.

Can UHMWPE be used outdoors?

Yes, especially black UHMWPE sheets, which contain carbon black for enhanced UV resistance. They can withstand outdoor exposure without significant degradation, making them suitable for marine, agricultural, and construction applications.

How is the price of UHMWPE sheets determined?

The cost depends on factors like thickness, size, color, and quantity. Thicker sheets and custom sizes generally cost more. Compared to metals, UHMWPE can be more expensive per unit weight but often provides better long-term value due to reduced maintenance and longer life.