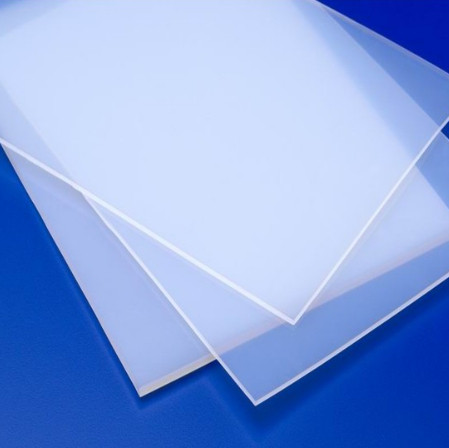

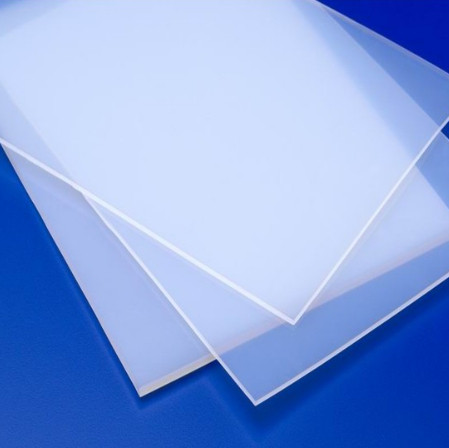

PFA (Perfluoroalkoxy) plastic sheet represents the pinnacle of fluoropolymer technology, offering exceptional chemical resistance, thermal stability, and electrical properties. This advanced material serves critical roles across numerous industries where performance under extreme conditions is non-negotiable.

| Sheet Size | Available Thickness | Standard Color | Special Colors Available |

|---|---|---|---|

| 12" x 12" | 0.010" - 0.125" | Natural | Black, White |

| 24" x 24" | 0.030" - 0.250" | Natural | Black, White |

| 36" x 36" | 0.060" - 0.500" | Natural | Black, White |

| 48" x 48" | 0.125" - 1.000" | Natural | Black, White |

| 48" x 96" | 0.250" - 2.000" | Natural | Black, White |

| Property | Value | Test Method | Units |

|---|---|---|---|

| Melting Point | 302-310 | ASTM D3418 | °C |

| Coefficient of Friction | 0.2 | ASTM D1894 | - |

| Hardness | D60 | ASTM D2240 | Shore D |

| Thermal Conductivity | 0.25 | ASTM C177 | W/m·K |

| Linear Thermal Expansion | 12.0 x 10-5 | ASTM D696 | cm/cm/°C |

| Volume Resistivity | >1018 | ASTM D257 | ohm·cm |

| Chemical | PFA Resistance | PTFE Resistance | FEP Resistance |

|---|---|---|---|

| Acetic Acid | Excellent | Excellent | Excellent |

| Hydrochloric Acid | Excellent | Excellent | Excellent |

| Sulfuric Acid | Excellent | Excellent | Excellent |

| Acetone | Excellent | Excellent | Excellent |

| Methanol | Excellent | Excellent | Excellent |

| Sodium Hydroxide | Excellent | Excellent | Excellent |

| Chlorine | Excellent | Excellent | Good |

| Ammonia | Excellent | Excellent | Good |

PFA plastic sheet serves critical functions across multiple sectors due to its exceptional performance characteristics. The material's unique combination of properties makes it indispensable in applications where other materials would fail.

PFA plastic sheet maintains its mechanical properties and chemical resistance at continuous service temperatures up to 260°C (500°F). For intermittent exposure, the material can withstand temperatures up to 285°C (545°F) for short durations without significant degradation. The low-temperature performance extends down to -200°C (-328°F), making it suitable for cryogenic applications.

Both PFA and PTFE offer excellent chemical resistance to virtually all industrial chemicals and solvents. However, PFA provides superior mechanical properties at elevated temperatures and better permeation resistance. While PTFE has slightly better thermal stability, PFA offers better stress crack resistance and can be melt-processed, unlike PTFE which requires sintering.

Yes, PFA plastic sheet can be machined using standard metalworking equipment with some modifications. Recommended practices include using sharp, high-speed steel tools with generous clearance angles. Coolants should be avoided as they can cause stress cracking. For best results, maintain slow feed rates and use fixtures to prevent deformation during machining operations.

Yes, specific grades of PFA plastic sheet are FDA compliant under CFR 21 and are suitable for food contact applications. These grades meet stringent purity requirements and do not leach harmful substances. PFA is commonly used in food processing equipment, pharmaceutical manufacturing, and laboratory applications where material purity is critical.

While PFA offers exceptional performance, it has some limitations to consider. The material has relatively low resistance to creep under sustained loads and may exhibit stress cracking when exposed to certain chemicals under stress. It also has high thermal expansion characteristics that must be accounted for in design. Additionally, PFA is susceptible to radiation damage and should not be used in high-radiation environments.

PFA plastic sheet has good resistance to ultraviolet radiation compared to many other plastics. However, prolonged exposure to direct sunlight may cause slight surface degradation and minor changes in mechanical properties over extended periods. For outdoor applications requiring maximum UV resistance, black PFA formulations containing carbon black provide enhanced protection against UV degradation.

PFA plastic sheet can be cleaned using most common solvents including isopropyl alcohol, acetone, and mild detergents. For thorough cleaning, a sequence of solvent washing followed by deionized water rinse is recommended. Avoid abrasive cleaners that could scratch the surface. For high-purity applications, vapor degreasing with appropriate solvents may be used following manufacturer guidelines.

PFA can be challenging to bond due to its non-stick properties and chemical inertness. Specialized surface treatments such as sodium etching or plasma treatment are required to achieve adequate adhesion. Thermal welding using hot air or butt welding techniques can successfully join PFA to itself. Adhesive bonding requires specialized fluoropolymer adhesives and proper surface preparation for reliable results.

When stored properly in original packaging away from direct sunlight, extreme temperatures, and chemical exposure, PFA plastic sheet has an essentially indefinite shelf life. The material does not degrade under normal storage conditions. Recommended storage conditions include temperatures between 15-30°C (59-86°F) with relative humidity below 60% and protection from UV light sources.

When machining PFA plastic sheet, proper ventilation is essential as the material can produce fine particles and may release decomposition products if overheated. Decomposition occurs above 380°C (716°F) and can release hazardous fumes. Always use appropriate personal protective equipment including respiratory protection and eye protection. Follow OSHA guidelines for particulate exposure and ensure adequate dust collection systems are in place.

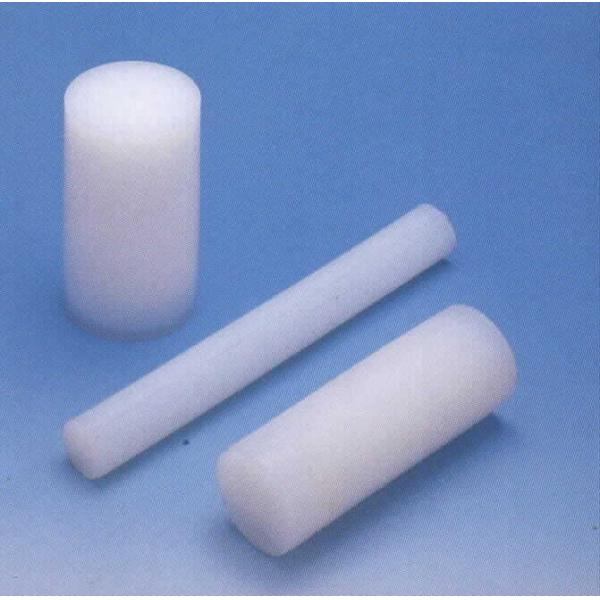

Our manufacturing capabilities extend beyond standard PFA plastic sheet offerings to include custom formulations and specialized products tailored to specific application requirements.

| Certification | Standard | Application | Testing Frequency |

|---|---|---|---|

| ISO 9001:2015 | Quality Management | All Products | Annual Audit |

| UL 94 | Flammability | Electrical Grades | Each Batch |

| FDA CFR 21 | Food Contact | Compliant Grades | Quarterly |

| ASTM D3307 | Material Standard | All Products | Each Production Run |

| RoHS Compliant | Environmental | All Products | Annual Testing |

| REACH Compliant | Chemical Safety | All Products | Continuous Monitoring |

Our commitment to quality extends throughout the manufacturing process, from raw material selection to final inspection. Each PFA plastic sheet undergoes rigorous testing to ensure it meets the specified requirements for thickness, dimensional stability, surface quality, and mechanical properties. Certificates of compliance are available for all shipments, providing documentation of material properties and quality assurance.

Our technical team provides comprehensive support for PFA plastic sheet applications, including material selection guidance, design assistance, and failure analysis. Engineering services include CAD modeling, prototyping, and custom fabrication solutions. With decades of experience in fluoropolymer applications, our experts can help optimize your design for maximum performance and cost-effectiveness.

```