A PTFE Sheet, or Polytetrafluoroethylene sheet, is a versatile industrial material known for its exceptional chemical resistance, low friction, and high-temperature stability. It is a form of Teflon® (a brand name for PTFE) manufactured in a flat, sheet-like form, making it ideal for gaskets, liners, bearings, and insulating components across various demanding industries.

Our PTFE sheets are available in various grades and forms to meet specific application requirements. Below are the detailed specifications.

| Parameter | Standard Value | Units | Remarks / Test Method |

|---|---|---|---|

| Density | 2.15 - 2.20 | g/cm³ | ASTM D792 |

| Tensile Strength | 25 - 35 | MPa | ASTM D638 |

| Elongation at Break | 300 - 500 | % | ASTM D638 |

| Coefficient of Friction (Dynamic) | 0.05 - 0.10 | - | Against Steel |

| Continuous Service Temperature | -200 to +260 | °C | Short term up to 300°C |

| Dielectric Strength | 40 - 60 | kV/mm | ASTM D149 |

| Volume Resistivity | >10¹⁸ | Ω·cm | ASTM D257 |

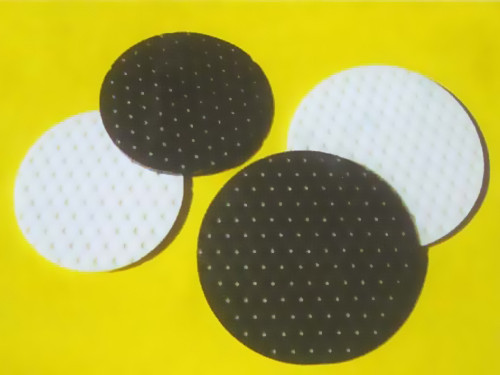

| Sheet Type | Standard Thickness | Standard Sheet Size | Color |

|---|---|---|---|

| Virgin (Unfilled) | 0.5mm, 1mm, 2mm, 3mm, 5mm, 10mm, 12mm, 20mm, 25mm, 50mm | 1000mm x 1000mm, 1200mm x 1200mm, 1500mm x 1500mm | White |

| Glass Filled (15%) | 1mm, 2mm, 3mm, 5mm, 10mm, 12mm | 1000mm x 1000mm | Beige/Brown |

| Carbon Filled (20%) | 1mm, 2mm, 3mm, 5mm, 10mm | 1000mm x 1000mm | Black |

| Bronze Filled (40%) | 3mm, 5mm, 10mm, 12mm, 20mm | 1000mm x 1000mm | Bronze |

To enhance specific mechanical properties, PTFE can be compounded with various filler materials.

What is the main difference between PTFE and Teflon?

Teflon is a brand name for PTFE (Polytetrafluoroethylene) owned by Chemours (formerly DuPont). Therefore, a PTFE sheet is a Teflon sheet, but not all PTFE products are branded as Teflon if they are manufactured by other companies.

Can PTFE sheets be used for food contact applications?

Yes, virgin (unfilled) PTFE sheets that comply with FDA regulations (21 CFR 177.1550) are safe for food contact. They are inert, non-toxic, and will not contaminate food products.

How does temperature affect a PTFE sheet?

PTFE sheets maintain their properties across an extremely wide temperature range from -200°C to +260°C. They do not become brittle at cryogenic temperatures and do not melt like a thermoplastic; instead, they begin to degrade slowly above 260°C.

Is PTFE sheet resistant to UV light and outdoor weathering?

Virgin PTFE has excellent resistance to UV light and weathering, making it suitable for long-term outdoor applications without significant degradation of its mechanical or electrical properties.

Can PTFE sheets be easily machined or cut to shape?

Yes, PTFE is a soft, ductile material that is very easy to machine using standard workshop tools like saws, lathes, drills, and punches. It can be cleanly sheared, skived, or die-cut into complex shapes for gaskets and seals.

How do you join or bond PTFE sheets together?

Bonding PTFE is challenging due to its non-stick nature. It typically requires specialized surface treatments like sodium etching (napping) or plasma treatment to create a bondable surface before using high-performance epoxies or adhesives. Mechanical fastening is often a more reliable method.

What is the tolerance for machined PTFE parts?

Standard machining tolerances for PTFE are typically around ±0.1mm. Tighter tolerances can be achieved for critical dimensions, but it's important to account for the material's relatively high coefficient of thermal expansion.

What is the "cold flow" or "creep" property of PTFE?

Cold flow, or creep, refers to the tendency of PTFE to slowly deform under a continuous mechanical load, even at room temperature. This is a key consideration for gasket design, where the bolt load must be maintained, or for bearings under constant pressure. Using filled PTFE grades can significantly reduce cold flow.

Why would I choose a filled PTFE sheet over a virgin one?

You would choose a filled PTFE sheet when your application requires improved mechanical properties. Fillers like glass, carbon, or bronze enhance wear resistance, reduce deformation under load (cold flow), increase hardness, and improve thermal conductivity, making them suitable for demanding bearing, seal, and piston ring applications.

Are PTFE sheets electrically conductive?

Virgin PTFE sheets are excellent electrical insulators. However, certain conductive fillers like carbon or certain metal powders can be added to create a static-dissipative or electrically conductive PTFE sheet.

What are the limitations of using a PTFE sheet?

The primary limitations include its relatively low mechanical strength compared to metals, susceptibility to cold flow under sustained load, poor radiation resistance, and difficulty in bonding without surface treatment. It is also not recommended for applications involving molten alkali metals or certain powerful fluorinating agents.

How does the cost of PTFE compare to other plastic sheets?

PTFE is generally more expensive than common industrial plastics like polyethylene (PE), polypropylene (PP), or PVC due to its superior performance properties and more complex manufacturing process. However, its long service life and reduced maintenance costs in harsh environments often make it a cost-effective solution overall.