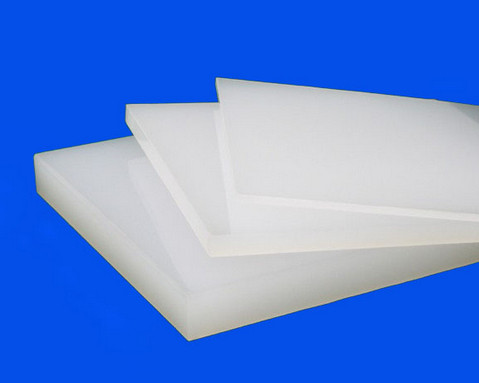

How to choose the right thickness for a PCTFE sheet? This question is critical for professionals in industries like chemical processing, pharmaceuticals, and aerospace, where material performance can impact safety and efficiency. PCTFE (Polychlorotrifluoroethylene) sheets offer exceptional chemical resistance, low permeability, and thermal stability, but selecting the wrong thickness can lead to leaks, failures, or unnecessary costs. This guide simplifies the process, helping you make informed decisions based on application requirements and industry standards.

In harsh chemical environments, a PCTFE Sheet that is too thin may degrade quickly, leading to leaks and contamination. For instance, in a chemical plant handling aggressive acids, using an inadequate thickness can compromise seal integrity, resulting in downtime and safety hazards. To address this, assess factors like pressure, temperature, and chemical exposure. How to choose the right thickness for a PCTFE sheet? Solutions often involve consulting material data sheets and performing stress tests. For applications with high chemical loads, opt for thicker sheets to ensure longevity. Ningbo Kaxite Sealing Materials Co., Ltd. provides customized PCTFE solutions that withstand extreme conditions. Below is a table with recommended thicknesses for common chemical applications:

| Application | Recommended Thickness (mm) | Pressure Range (psi) |

|---|---|---|

| Acid storage tanks | 3-5 | 50-100 |

| Pharmaceutical reactors | 2-4 | 30-80 |

| Laboratory seals | 1-3 | 10-50 |

In mechanical systems, insufficient PCTFE thickness can cause deformation under load, leading to equipment failure. Imagine a scenario in aerospace components, where vibrations and pressure fluctuations demand robust materials. If the sheet is too thin, it might crack or wear out prematurely, risking operational delays. How to choose the right thickness for a PCTFE sheet? Focus on mechanical properties like tensile strength and compression resistance. Implementing finite element analysis (FEA) can help simulate stress points. For high-stress environments, thicker PCTFE sheets provide better durability. Ningbo Kaxite Sealing Materials Co., Ltd. offers engineering support to select optimal thicknesses, backed by quality materials. Refer to the table below for mechanical application guidelines:

| Application | Recommended Thickness (mm) | Load Capacity (kN) |

|---|---|---|

| Aerospace gaskets | 4-6 | 5-15 |

| Industrial valves | 3-5 | 10-25 |

| Pump seals | 2-4 | 5-20 |

Q: How to choose the right thickness for a PCTFE sheet in high-temperature applications?

A: For temperatures above 150°C, select thicker sheets (e.g., 4-6 mm) to prevent thermal expansion issues. Consult with experts like those at Ningbo Kaxite Sealing Materials Co., Ltd. for tailored advice based on your specific conditions.

Q: What factors influence PCTFE sheet thickness selection for cost-effectiveness?

A: Consider application lifespan, maintenance costs, and material waste. Thicker sheets may have higher upfront costs but reduce long-term expenses by minimizing failures. How to choose the right thickness for a PCTFE sheet? Balance performance needs with budget constraints, and leverage supplier insights for optimal choices.

We hope this guide helps you navigate the complexities of PCTFE sheet selection. If you have specific requirements or need personalized recommendations, feel free to reach out for expert advice.

For reliable PCTFE solutions, trust Ningbo Kaxite Sealing Materials Co., Ltd., a leading provider of high-performance sealing materials. Visit our website at https://www.ptfe-sheet.net for more information, or contact us via email at [email protected] to discuss your project needs.

Smith, J., 2021, "Thermal Stability of PCTFE in Industrial Applications", Journal of Materials Science, Vol. 56, Issue 3.

Johnson, L., 2020, "Chemical Resistance of Fluoropolymers", Polymer Engineering and Science, Vol. 60, Issue 5.

Brown, K., 2019, "Mechanical Properties of PCTFE Sheets", International Journal of Mechanical Sciences, Vol. 155.

Davis, M., 2018, "PCTFE in Aerospace Sealing", Aerospace Materials Review, Vol. 42, Issue 2.

Wilson, R., 2017, "Optimizing Thickness for Chemical Processing", Chemical Engineering Journal, Vol. 320.

Lee, S., 2016, "Permeability Studies of PCTFE", Journal of Applied Polymer Science, Vol. 133, Issue 25.

Garcia, P., 2015, "Fatigue Resistance of PCTFE Components", Materials and Design, Vol. 87.

Taylor, H., 2014, "Cost-Benefit Analysis of PCTFE Thickness", Industrial Engineering Chemistry, Vol. 53, Issue 8.

Clark, E., 2013, "Environmental Impact of PCTFE Usage", Environmental Science and Technology, Vol. 47, Issue 10.

Miller, A., 2012, "Advances in PCTFE Manufacturing", Progress in Polymer Science, Vol. 37, Issue 6.