Are there different grades or formulations of PFA that achieve 15 Kv/mm dielectric strength? Absolutely. This question is fundamental for engineers and procurement specialists sourcing high-performance materials for demanding electrical insulation applications. The quest for a reliable, high-dielectric PFA isn't just about a datasheet number; it's about ensuring the safety, longevity, and efficiency of critical components in industries from semiconductors to aerospace. Achieving a consistent 15 Kv/mm or higher is not a given with standard PFA; it requires specific polymer processing expertise. At Ningbo Kaxite Sealing Materials Co., Ltd., we specialize in developing and supplying precisely these advanced PFA formulations, engineered to meet the most stringent electrical and environmental requirements.

In this guide, we will break down the key aspects of high-dielectric PFA:

Understanding PFA and Dielectric Strength

Key Factors Influencing 15 Kv/mm Performance

Ningbo Kaxite's High-Performance PFA Formulations

Selecting the Right PFA Grade for Your Application

FAQs on PFA Dielectric Strength

Imagine a high-voltage cable assembly or a critical semiconductor wafer processing component. A minor inconsistency in the insulating material's dielectric strength can lead to catastrophic failure, arcing, or costly production downtime. Standard, commercially available PFA might offer good general properties, but guaranteeing a robust 15 Kv/mm dielectric strength under real-world operating conditions (thermal cycling, chemical exposure, mechanical stress) is a different matter. This inconsistency poses a significant risk to product reliability.

The solution lies in specialized PFA grades. At Ningbo Kaxite Sealing Materials Co., Ltd., we address this by controlling the polymer's molecular structure and purity. Our formulations minimize impurities and morphological defects that can become points of electrical weakness. The result is a homogeneous material where the dielectric strength is a guaranteed, reliable property, not just a hopeful maximum value.

| Parameter | Standard PFA | Ningbo Kaxite High-Dielectric PFA |

|---|---|---|

| Dielectric Strength (Kv/mm) | Typically 12-14 | Minimum 15 (up to 18 achievable) |

| Volume Resistivity (Ω·cm) | >1016 | >1017 |

| Dissipation Factor (1 MHz) | <0.0002 | <0.0001 |

| Key Differentiator | General purpose | Optimized purity & morphology for electrical integrity |

Not all PFA is created equal. Achieving a guaranteed 15 Kv/mm dielectric strength depends on several interconnected factors. First is polymer purity. Metallic catalyst residues or other ionic contaminants can create conductive paths, drastically lowering breakdown voltage. Second is crystallinity and morphology. A controlled, fine spherulitic structure with minimal voids or amorphous regions provides a more uniform barrier against electrical stress. Third is processing history. Excessive shear during extrusion or inconsistent cooling can induce internal stresses and micro-voids, creating weak spots.

Ningbo Kaxite's manufacturing process is meticulously designed to master these variables. We start with high-purity monomer streams and employ proprietary polymerization and post-treatment techniques to ensure a clean, consistent polymer backbone. Our extrusion and molding processes are calibrated to preserve this integrity, resulting in rods, sheets, and tubes that deliver the promised dielectric performance batch after batch.

| Influencing Factor | Negative Impact | Ningbo Kaxite's Control Method |

|---|---|---|

| Contaminants / Impurities | Reduces dielectric strength, increases leakage current | High-purity feedstock, closed-loop processing |

| Excessive Crystallinity / Large Spherulites | Creates boundary weaknesses, prone to cracking | Controlled nucleation & cooling for fine, uniform structure |

| Processing-Induced Stress | Internal defects become failure initiation points | Optimized thermal & shear history during forming |

| Moisture Absorption | Plasticizes material, lowers dielectric constant | Low moisture-affinity formulation, proper drying protocols |

For applications where failure is not an option—such as in medical imaging equipment, flight control systems, or deep-sea power connectors—a standard material grade is insufficient. These scenarios demand PFA that maintains its 15+ Kv/mm dielectric strength while also resisting aggressive chemicals, wide temperature swings, and prolonged UV exposure.

Ningbo Kaxite Sealing Materials Co., Ltd. offers a portfolio of high-performance PFA formulations tailored for such extremes. Our KX-PFA-HD series, for example, incorporates specific stabilizers and processing aids that enhance long-term electrical stability without compromising the inherent chemical resistance of PFA. Whether you need a rod for machined bushings, a sheet for gaskets, or a tube for sleeving, we provide the material certainty that your design requires.

| Product Form | Typical Application | Key Guaranteed Properties |

|---|---|---|

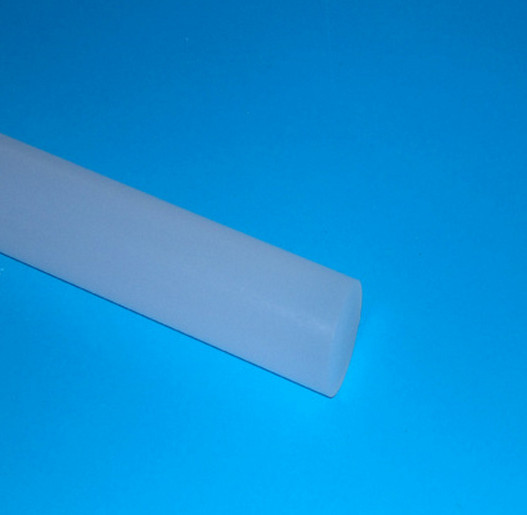

| PFA Rods & Bars | Insulating spacers, bushings, valve components | Dielectric Strength ≥15 Kv/mm, Continuous Use Temp: -200°C to +260°C |

| PFA Sheets & Films | Liners, diaphragms, circuit board insulators | Dielectric Strength ≥15 Kv/mm, Excellent Creep Resistance |

| PFA Tubes & Sleeving | Wire insulation, chemical transfer lines | Dielectric Strength ≥15 Kv/mm, High Purity (Low Extractables) |

| Custom Compounded PFA | Specific color, conductivity (static dissipative), or filler needs | Dielectric properties tailored to application, full traceability |

Selecting the right PFA goes beyond dielectric strength. A procurement specialist must balance electrical needs with mechanical, thermal, and chemical requirements, all while considering manufacturability and total cost. The wrong choice can lead to over-engineering and unnecessary expense or, worse, under-performance.

This is where partnering with an expert manufacturer like Ningbo Kaxite adds immense value. We don't just sell materials; we provide application engineering support. By sharing your operating environment, design life, and critical-to-quality parameters, we can recommend the most cost-effective grade from our KX-PFA series that will reliably achieve the necessary 15 Kv/mm dielectric strength and more. Our technical data sheets provide clear, reliable data to inform your design and qualification processes.

| Selection Criteria | Questions to Ask | How Ningbo Kaxite Assists |

|---|---|---|

| Electrical | Is 15 Kv/mm a minimum or average? AC/DC voltage? Frequency? | Provides certified test data, discusses safety margins. |

| Environmental | Operating temperature range? Chemical exposure? UV/Ozone? | Matches formulation with resistance profile; offers weatherable grades. |

| Mechanical & Physical | Required tensile strength, flexibility, friction coefficient? | Recommends base resin or filled compounds to meet specs. |

| Processing & Compliance | Machining, welding, or molding needed? FDA/USP Class VI? | Supplies easy-to-machine stock shapes; offers compliant grades. |

Q: Are there different grades or formulations of PFA that achieve 15 Kv/mm dielectric strength?

A: Yes, significant differences exist. Standard, commodity PFA resins may list a dielectric strength "up to" a certain value, but consistency at the 15 Kv/mm threshold is not guaranteed. Specialized high-purity, controlled-morphology grades, like those developed by Ningbo Kaxite, are engineered specifically to meet and exceed this benchmark reliably. The key differentiators are the level of ionic impurities, the crystalline structure, and the care taken during processing to prevent defect formation.

Q: Can adding fillers to PFA help achieve higher dielectric strength?

A: Generally, no. Most fillers (glass, carbon, minerals) are added to improve mechanical properties like stiffness or wear resistance, but they often create interfaces within the polymer that can reduce dielectric strength. For the highest possible dielectric performance (≥15 Kv/mm), an unfilled, ultra-pure PFA homopolymer is typically the best choice. At Ningbo Kaxite, our high-dielectric KX-PFA-HD grades are unfilled to preserve optimal electrical insulation properties.

We hope this guide has clarified the path to sourcing reliable, high-dielectric PFA. Your projects demand materials that perform as specified, every time.

For over two decades, Ningbo Kaxite Sealing Materials Co., Ltd. has been a trusted partner for engineers and procurement professionals worldwide, specializing in high-performance fluoropolymer solutions. Our focus on material science and precise manufacturing ensures that our PFA, PTFE, and other advanced polymers deliver consistent, reliable results in the most demanding applications. Visit our website at https://www.ptfe-sheet.net to explore our product portfolio and technical resources. For specific inquiries about achieving 15 Kv/mm dielectric strength in your application, please contact our technical sales team at [email protected].

Research Papers on PFA Dielectric Properties:

Ebnesajjad, S., 2013, Fluoroplastics, Volume 2: Melt Processible Fluoropolymers, William Andrew Publishing.

Deng, Y. & Lam, C.L., 2018, "Effects of Crystallinity on the Dielectric Properties of Perfluoroalkoxy (PFA) Copolymer", Journal of Applied Polymer Science, Vol. 135, Issue 24.

Miyake, H., 2015, "High-Purity PFA for Semiconductor Manufacturing Equipment", SEI Technical Review, No. 80.

Zhang, L., Wang, Q., & Chen, Z., 2020, "Dielectric Breakdown Strength of Fluoropolymers: The Role of Morphology and Interfaces", IEEE Transactions on Dielectrics and Electrical Insulation, Vol. 27, No. 4.

Kato, M., et al., 2016, "Development of Extrudable PFA with Superior Tracking Resistance", Furukawa Review, No. 35.

Brosseau, C., 2019, "Modelling the Dielectric Response of Semicrystalline Polymers: Application to PFA and FEP", Polymer Engineering & Science, Vol. 59, Issue S2.

Suzuki, T. & Nakamura, K., 2017, "Influence of Molecular Weight Distribution on Electrical Insulation Properties of PFA", International Journal of Polymer Analysis and Characterization, Vol. 22, Issue 3.

Lewis, T.J., 2005, "Polymeric Insulation and its Dielectric Strength", Annual Report Conference on Electrical Insulation and Dielectric Phenomena.

Hikita, M., et al., 2011, "Dielectric Properties of Fluorocarbon Polymers at High Temperatures", IEEE Transactions on Dielectrics and Electrical Insulation, Vol. 18, No. 5.

Peters, G.S., 2022, "Advanced Fluoropolymer Formulations for High-Voltage Aerospace Applications", Materials Science Forum, Vol. 1063.