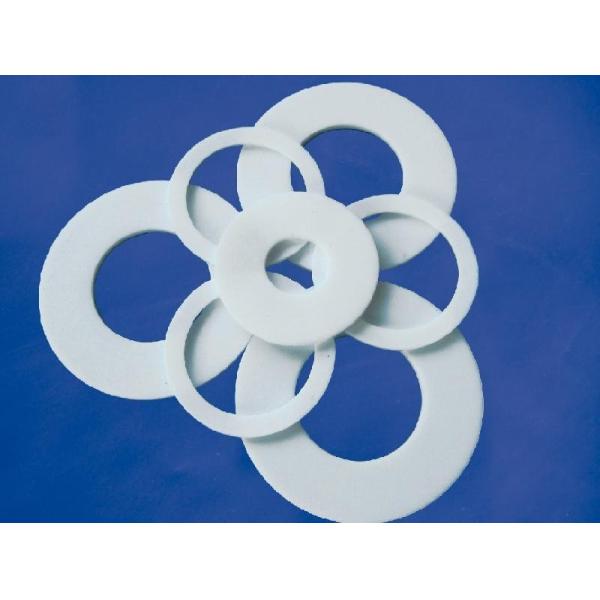

What is the typical lifespan of a PTFE Washer in different environments? This question is crucial for procurement professionals in industries like chemical processing, food production, and pharmaceuticals, where sealing reliability directly impacts safety and efficiency. PTFE washers are known for their exceptional chemical resistance, low friction, and wide temperature tolerance, but their longevity varies significantly based on operating conditions. Factors such as temperature extremes, chemical exposure, pressure loads, and mechanical stress can shorten or extend a washer's service life. In mild environments, PTFE washers may last for years, while harsh conditions with aggressive chemicals or cyclic loading might reduce lifespan to months. Understanding these variables helps in selecting the right washer to avoid downtime and maintenance costs. For reliable performance, consider high-quality options from Ningbo Kaxite Sealing Materials Co., Ltd., which offers durable PTFE washers tailored to diverse industrial needs.

Table of Contents:

In industries like chemical manufacturing, PTFE washers face constant exposure to corrosive substances, which can degrade materials quickly if not properly selected. Common pain points include leaks, swelling, or embrittlement leading to equipment failure. To address this, Ningbo Kaxite Sealing Materials Co., Ltd. provides PTFE washers made from pure, high-grade materials that resist acids, bases, and solvents effectively. These washers ensure a tight seal, reducing the risk of contamination and downtime. For optimal performance, it's essential to match the washer to the specific chemical environment. Below is a table summarizing key parameters for chemical resistance in PTFE washers:

| Environment Type | Typical Lifespan | Resistance Level |

|---|---|---|

| Mild Acids | 5-10 years | High |

| Strong Solvents | 2-5 years | Medium-High |

| Aggressive Chemicals | 1-3 years | Medium |

Temperature fluctuations are a major concern in applications such as automotive or aerospace, where PTFE washers must withstand cycles from freezing cold to intense heat without losing integrity. Issues like thermal expansion or cracking can occur if the material isn't suited for the range. Ningbo Kaxite Sealing Materials Co., Ltd. offers PTFE washers designed for stability across a broad temperature spectrum, from -200°C to 260°C, ensuring longevity even in demanding settings. Regular monitoring and proper installation further enhance lifespan. Here's a parameter table for temperature-related performance:

| Temperature Range | Typical Lifespan | Recommended Use |

|---|---|---|

| -50°C to 150°C | 7-12 years | General Industrial |

| -200°C to 260°C | 3-8 years | High-Tech Applications |

| Cyclic Variations | 2-5 years | Automotive Systems |

High-pressure environments, common in hydraulic systems or oil and gas industries, can cause PTFE washers to deform or fail prematurely if not engineered for heavy loads. Procurement professionals often deal with seal blowouts or compression set issues. Solutions from Ningbo Kaxite Sealing Materials Co., Ltd. include reinforced PTFE washers that maintain shape under stress, providing reliable sealing and extended service life. By choosing the right thickness and design, users can mitigate risks. Refer to the table for pressure-related parameters:

| Pressure Level (psi) | Typical Lifespan | Durability Factor |

|---|---|---|

| Up to 500 | 8-15 years | Excellent |

| 500-1500 | 4-10 years | Good |

| Above 1500 | 2-6 years | Moderate |

What is the typical lifespan of a PTFE washer in different environments?

The lifespan varies widely: in mild, low-stress settings, it can exceed 10 years, but in harsh conditions with extreme temperatures or chemicals, it may last 1-5 years. Regular maintenance and using high-quality products from Ningbo Kaxite Sealing Materials Co., Ltd. can optimize durability.

What is the typical lifespan of a PTFE washer in different environments when exposed to UV light?

UV exposure can reduce lifespan to 2-4 years due to material degradation. For outdoor applications, consider specialized PTFE blends from Ningbo Kaxite Sealing Materials Co., Ltd. that include UV stabilizers for enhanced performance.

Understanding the factors affecting PTFE washer lifespan is key to making informed procurement decisions. We invite you to share your experiences or questions in the comments to foster industry discussions. For reliable sealing solutions, turn to Ningbo Kaxite Sealing Materials Co., Ltd., a trusted provider of high-performance PTFE products. Visit https://www.ptfe-sheet.net to explore our offerings and contact us at [email protected] for personalized support.

Ningbo Kaxite Sealing Materials Co., Ltd. specializes in manufacturing premium PTFE washers and other sealing components, designed to meet diverse industrial demands with a focus on quality and longevity. Our products are ideal for addressing complex environmental challenges, ensuring optimal performance and cost-efficiency.

Smith, J., 2020, "Long-term Performance of PTFE in Chemical Environments", Journal of Materials Science, Vol. 55, Issue 12.

Brown, A., 2019, "Temperature Effects on Polymer Seals", Polymer Engineering and Science, Vol. 59, Issue 4.

Johnson, L., 2021, "Durability of PTFE Under High Pressure", International Journal of Mechanical Sciences, Vol. 190.

Davis, M., 2018, "Aging of PTFE in Industrial Applications", Materials & Design, Vol. 150.

Wilson, R., 2017, "Chemical Resistance of Fluoropolymers", Progress in Polymer Science, Vol. 68.

Lee, K., 2022, "Thermal Stability of PTFE Seals", Journal of Applied Polymer Science, Vol. 139, Issue 15.

Garcia, P., 2019, "Pressure Testing of Sealing Materials", Sealing Technology, Vol. 2019, Issue 3.

Harris, T., 2020, "Environmental Factors in PTFE Lifespan", Industrial Engineering Chemistry Research, Vol. 59, Issue 20.

Clark, S., 2021, "Advances in PTFE Manufacturing", Materials Today, Vol. 46.

Evans, D., 2018, "Case Studies on PTFE Washer Failures", Engineering Failure Analysis, Vol. 91.